Partial load calibration results

Advantages of partial load calibration

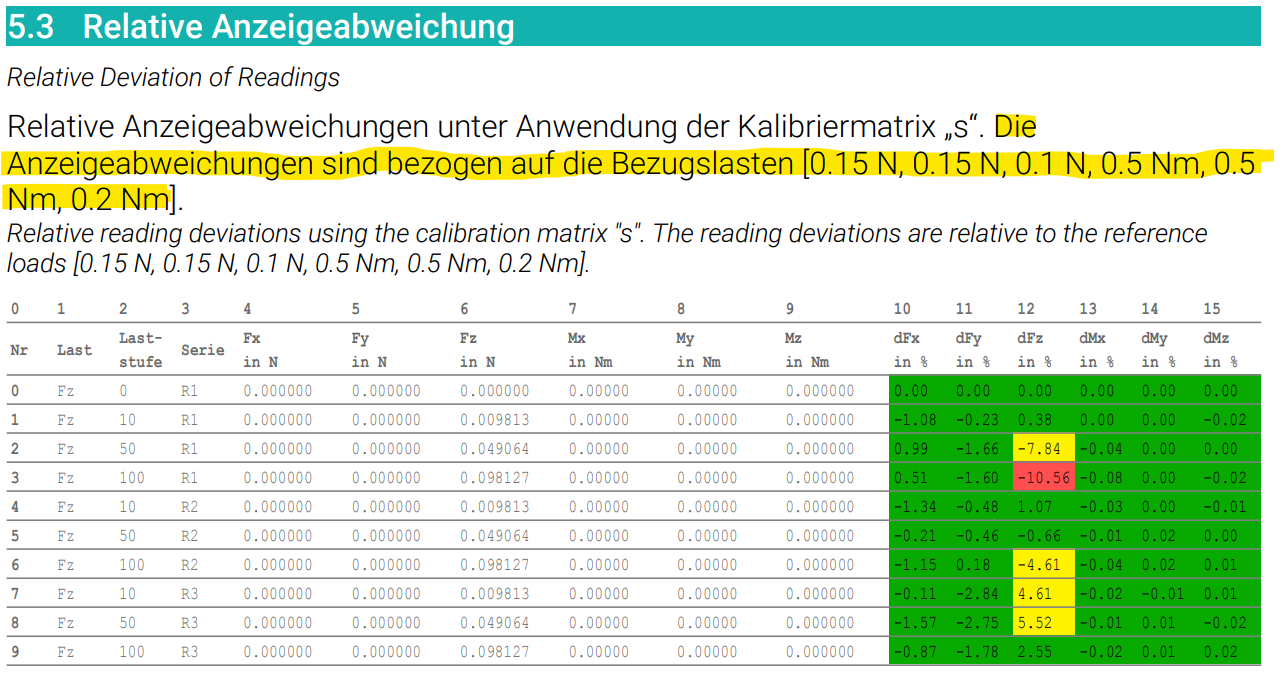

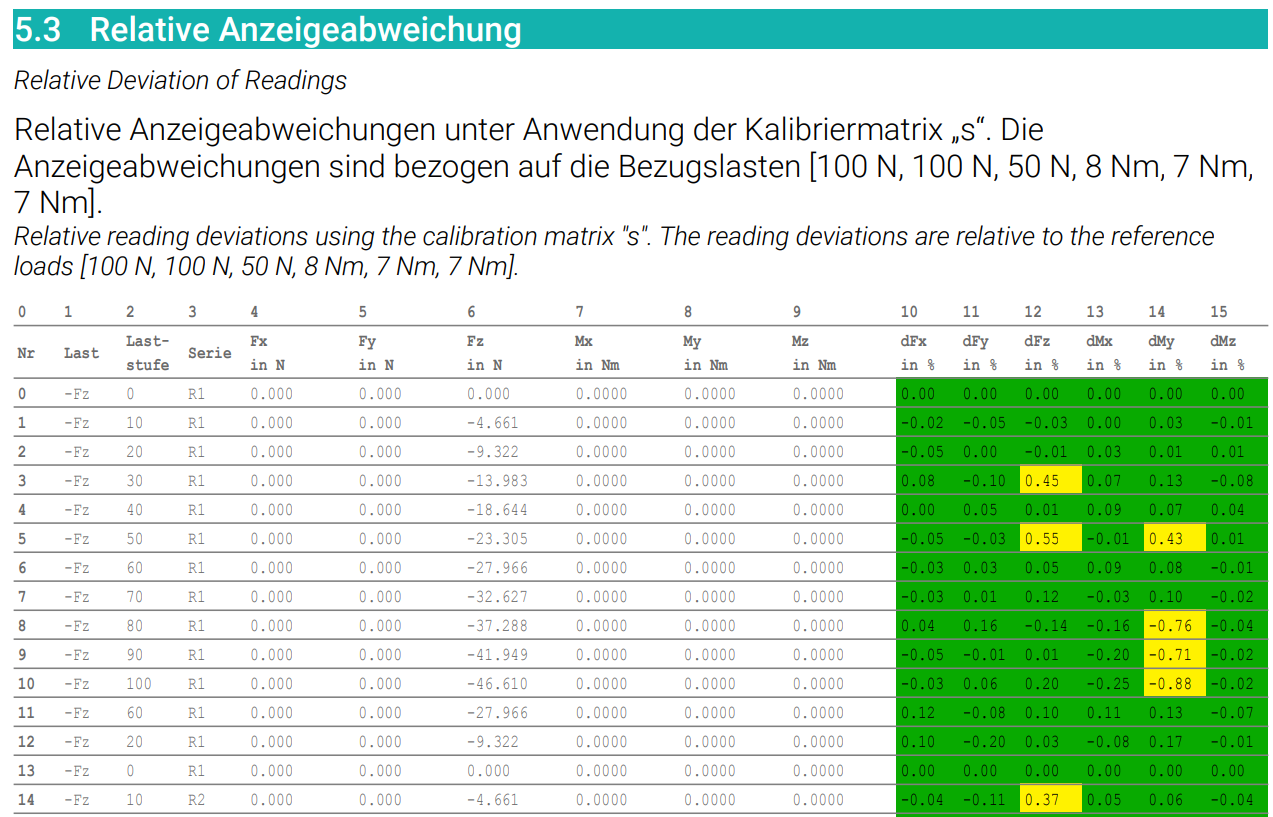

When calibrating the force/torque sensor at a load level of 1% of its rated load, the sensor's deviation is not necessarily 100 times higher than when calibrated at rated loads.

The results of calibration under partial load can even be better than calibration under rated load.

The reasons for this finding are:

Due to the high resolution, the noise amplitude only slightly affects the reproducibility of the results.

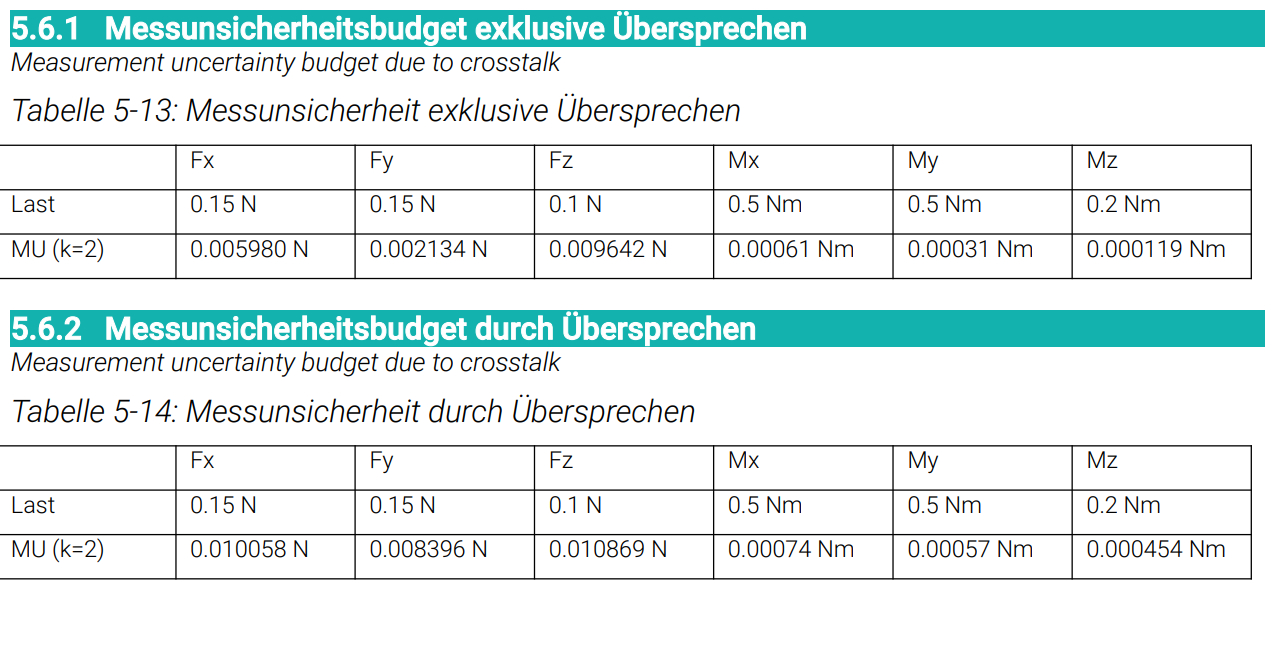

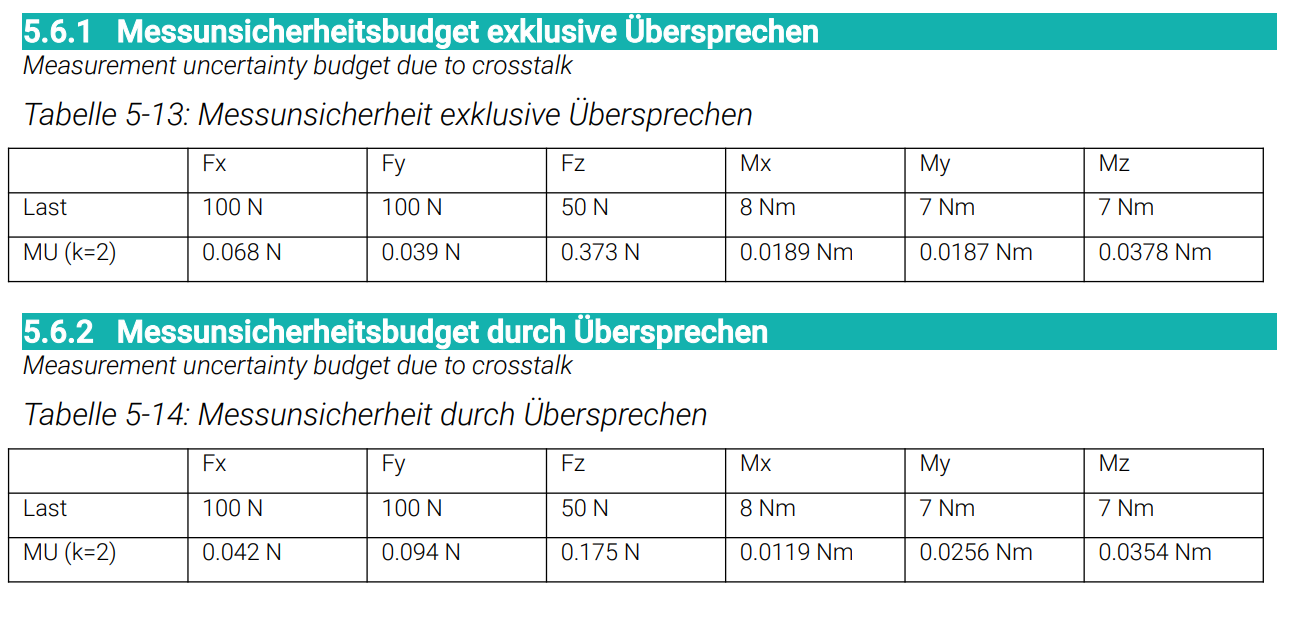

Crosstalk also depends on the load amplitude. Applying partial loads also reduces crosstalk.

By applying the linear compensation calculation to a smaller section of the sensor characteristic curve, deviations and crosstalk are also reduced: Any nonlinear characteristic curve can be better approximated using multiple linear segments than would be possible with a compensation calculation for the entire characteristic curve up to the rated load.

Disadvantages of partial load calibration

The temperature-related drift of the zero signal has a greater impact relative to partial load than relative to nominal load.

Accordingly, the measurement should be short, e.g., a few minutes. The zero signal should be checked at the beginning and end of the measurement to estimate the influence of zero signal drift.