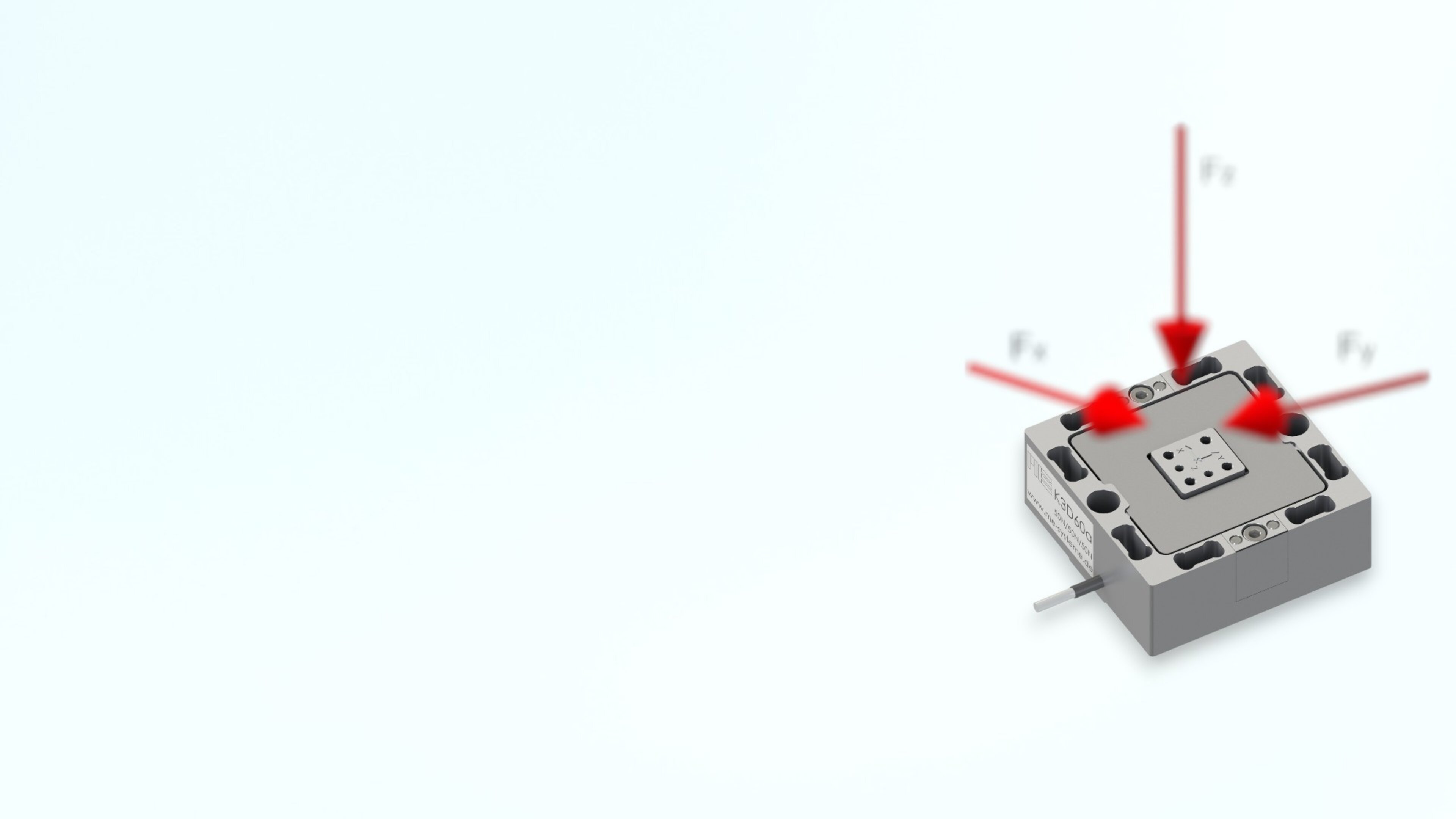

Construction of 3D force sensors

With the 3D force sensors from ME-Meßsysteme GmbH, it is possible to measure forces in three spatial directions (x, y, z). The 3D sensors are equipped with full-bridge strain gauges. The signals from the full-bridge strain gauges each correspond to a force component in the x, y, and z directions.

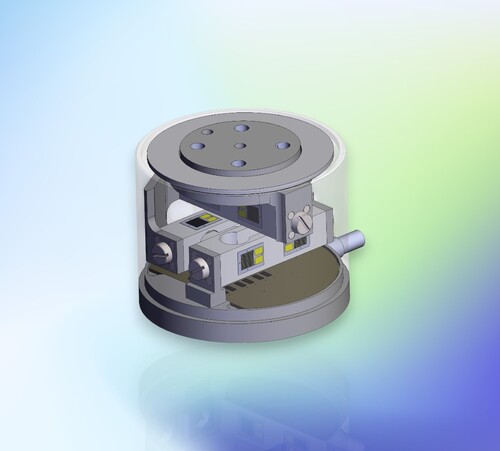

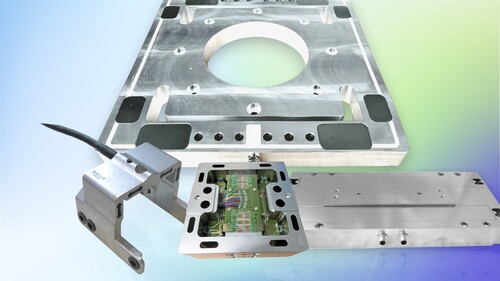

Spring joint guide

The deformation body of the 3D force sensor is designed to have a spring-joint guide equipped with strain gauges in three mutually perpendicular orientations. The spring-joint guides and the arrangement and interconnection of the strain gauges enable a vector decomposition of the applied force vector across the three axes of the force sensor.