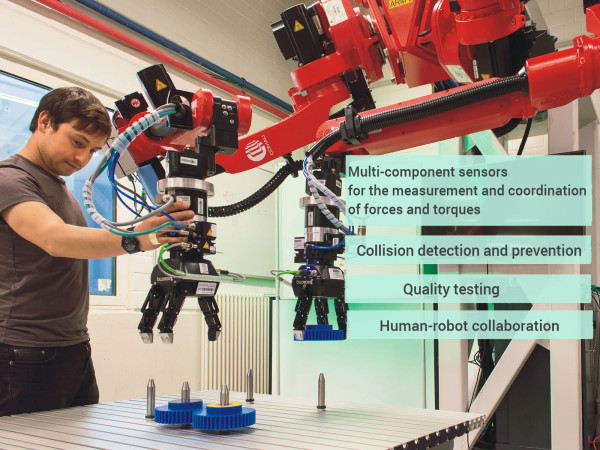

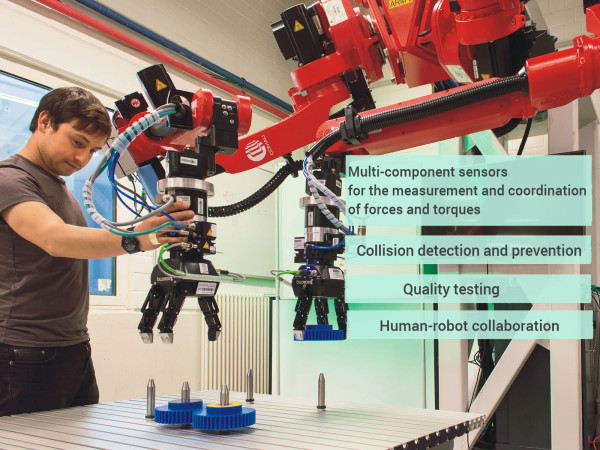

ROBOTICS and AUTOMATION

POWERFUL MEASUREMENT SYSTEM

3-axis, 6-component: enabling simultaneous force and torque measurement

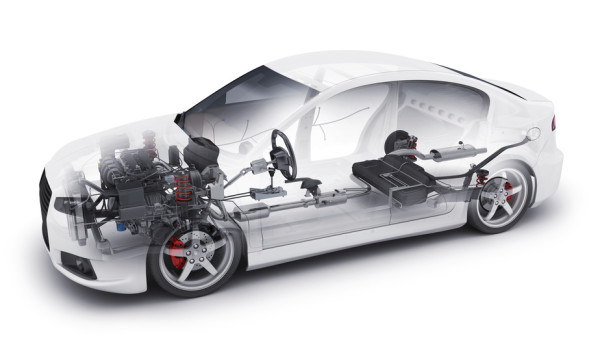

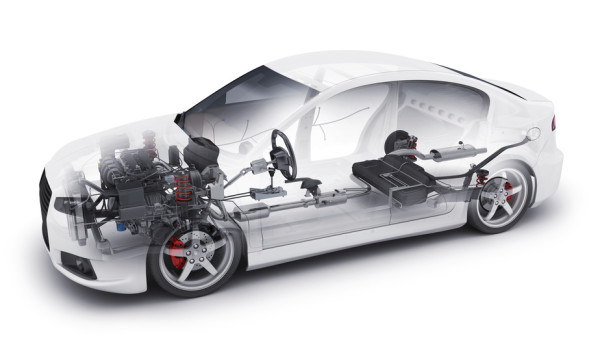

AUTOMOTIVE

Force and torque transducers fulfill the important metrological tasks in production and quality assurance in automotive engineering.

- Force measurements during the test drives;

- acceleration

- Three-point bending tests, peripheral shear tests or penetration tests and pull-out tests

Precise and high-resolution measuring systems ensure good driving dynamics of the vehicle.

AEROSPACE

Especially aviation and space research requires precise force, acceleration and torque measurement.

ME force measurement technologies support numerous R&D projects in this sector.

- various measurements in the rocket test rig such. B.

- Shear measurement of the rocket engine;

MEDICINE

When testing and operating devices in medical technology, multidimensional and multicomponent sensors are indispensable. Three- and six-axis force and torque transducers allow the positioning and alignment of the devices, such as e. g. X-ray devices. These intelligent "sensors" detect the forces and torques in three directions X, Y and Z and serve collision protection.

WIND POWER

Aerodynamic tests in wind tunnels require a particularly high level of measuring accuracy.

Multi-component sensors in conjunction with the real-time measuring devices allow the force and torque effects on the measurement objects in a flow field to be examined precisely and in a time-synchronized manner.